The Challenge

Many shippers face challenges in managing and measuring freight transportation performance. The scorecarding process is often manual and time-consuming, leading to wasted resources and unproductive meetings with business partners. One shipper struggling with these challenges was an Enterprise Beverage Manufacturer (AKA “Enterprise Shipper”). Although this Enterprise Shipper is a leader in developing cutting-edge procurement strategies and embracing innovation, their process for measuring service-level performance was fragmented and laborious. Critical shipment and order data was logged in hundreds of spreadsheets and distributed across multiple stakeholders, leading to a time-consuming and error-prone cycle of retrieving, analyzing, and acting on the data.

As a result, the company had one analyst spending 15-20 hours per week on scorecarding and carrier management alone. Scorecards were then passed to 4 additional employees across procurement regions to manage rebuttals, and escalations sometimes involved upper-level management. On any given week, 5-13 employees worked on this process, eating up valuable resources that could have been allocated more productively elsewhere.

Additionally, the volume of inaccurate, untrustworthy data made it difficult for this Enterprise Shipper to make timely procurement decisions, identify responsible parties for service failures, and improve overall transportation performance within their carrier network.

The Solution

To address these aforementioned challenges, the Enterprise Beverage Manufacturer partnered with Isometric Technologies (ISO) to improve their logistics data quality, boost operational efficiency, and better understand their transportation network performance. ISO provided the Enterprise Shipper with a single source-of-truth platform to reconcile service-level performance data with their carrier network.

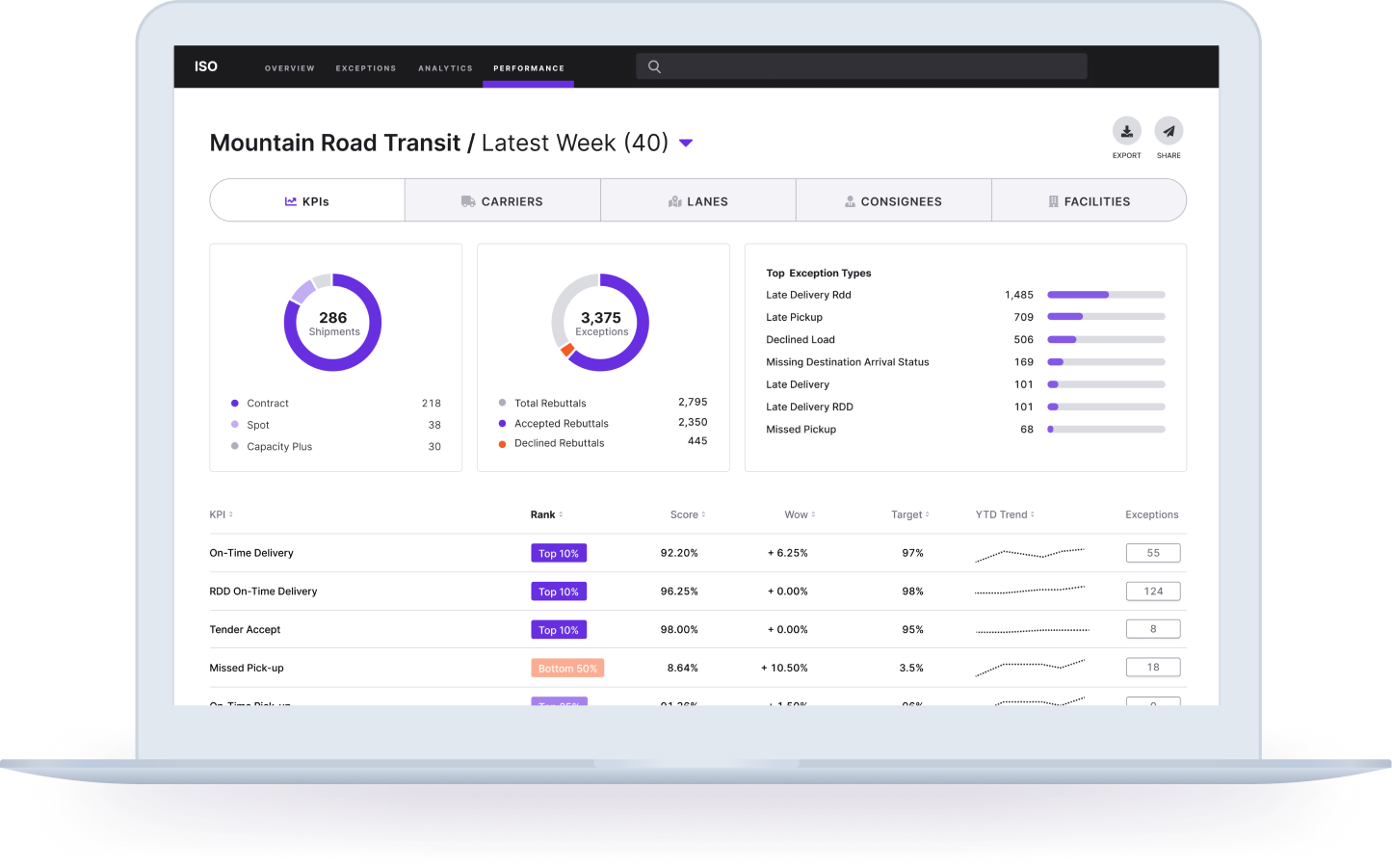

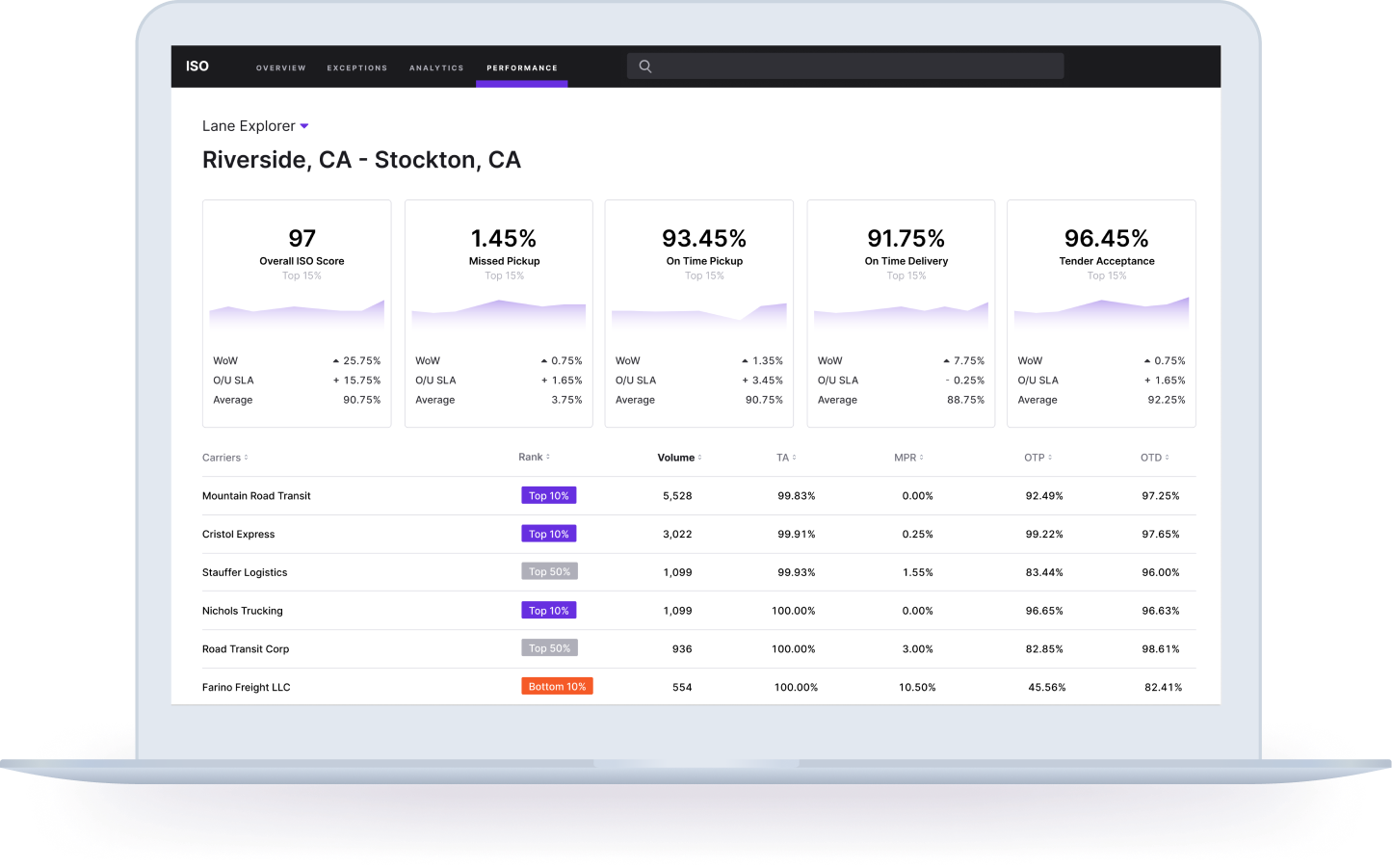

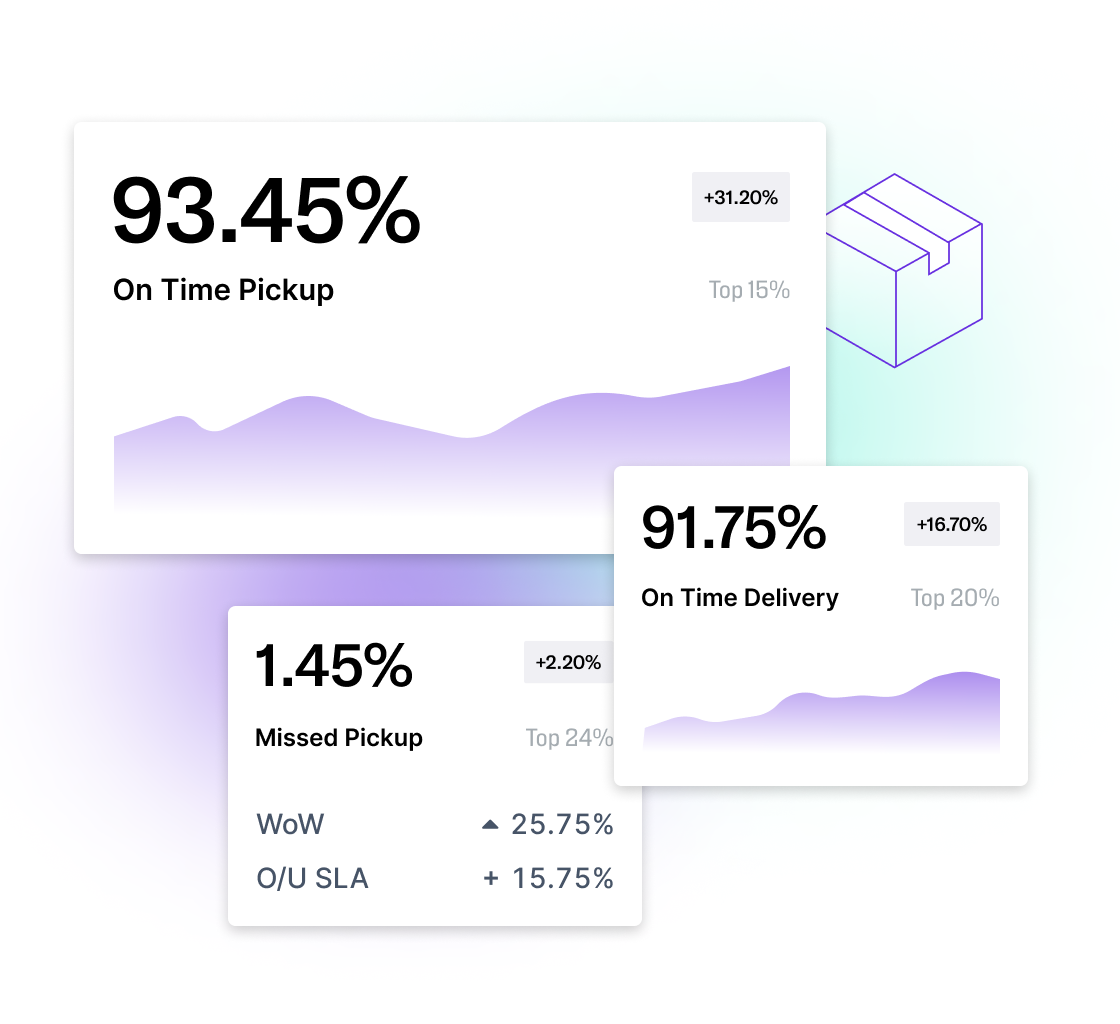

ISO’s Logistics Performance Intelligence platform houses the Enterprise Shipper’s internal and external KPIs and SLAs, along with associated penalties, then ingests data from the Shipper’s internal systems and generates exceptions when shipments fail to meet these pre-defined standards. Carriers are then given the opportunity to audit these exceptions, submit rebuttals, and provide reason codes for service failures.

The digitization of the Enterprise Shipper’s scorecarding process yielded immediate results: decreasing hours needed for scorecard creation and management from ~5,000 hours per year to ~2,000 hours per year.

To date, 21% of the Enterprise Shipper’s exceptions have been overturned with ISO’s data reconciliation workflow. Meaning the responsible party and/or reason code for those service failures have been altered from their original status, resulting in cleaner, more reliable data. Carriers have also benefitted from this workflow; the ability to correct inaccurate exceptions on a shared platform materially impacts KPIs, improves trust with the Enterprise Shipper, and gives back time to both parties to resolve service issues proactively.

In addition, the Enterprise Shipper utilized ISO’s “QBR in a Box” solution, which offers pre-built reports that can be shared with carriers ahead of quarterly business reviews. This significantly cut the time needed for QBR preparation from 30-60 minutes per carrier to 5-10 minutes. Because ISO’s platform allows shippers and carriers to operate on the same set of data, they can focus on creating action plans to correct network inefficiencies instead of arguing about data accuracy.

In conclusion, this Enterprise Shipper’s collaboration with ISO has allowed them to proactively resolve service issues and improve their procurement processes with trustworthy performance data.